Power supply secondary

side and scanning section troubleshooting – circuit description

SONY KV27FV15, KV32FV15, KV32FS10, KV32XBR250, KV36XBR250, KV32FV15, KV36FV15, KV36FS10

Secondary Voltages

+135 Volts

The

signal from the winding of T605/10 and 11 is applied across D643 Bridge

Rectifier and C643 and L642 filter the rectified voltage. D648 is a 150-volt

zener diode that will limit the voltage to 150 volts in case of a failure that

causes the B+ to rise. This voltage is then sent through R652 and output from

the G board at CN641/1 and 2. The voltage is used on the G board by the

protection and regulation circuits and is also used to produce the +33 volt

line on the A board.

+12

Volts

D651

and D652 rectify the signal from T605/7 and 8. This voltage is filtered by C658

and input to IC650 12-Volt Regulator. IC650 outputs a regulated 12 volts that

is filtered by C661 and output from the G board at CN641/8.

+9

Volts

The

signal from T605/7 and 8 is applied to D642 through two similar parallel networks

consisting of L650 and R670, and L651 and R670. This rectified voltage is then

applied to the input of IC641 9-Volt Regulator. The output of this IC outputs

9.6 volts to L652 and also to CN641/6 and 7.

The voltage is 9.6

instead of 9 because D647 is connected between the ground pin of IC641 9 Volt

Regulator and ground.

+9

Volt Protections

The

+9 volt line also is monitored for OCP. Using the voltage drop across R680,

R681 and R644 to control the conduction of Q649 does this. When the amount of

current drawn on the 9 volt line is sufficient to cause Q649 to conduct, Q650

will be turned ON. This places a LOW on the inhibit line of IC641 9 Volt

Regulator. When there is a LOW present at this pin, the output of IC641 is

disabled.

+5

Volts

The

+5 volt line will not be discussed since it is not used in the set.

Audio

B+

The

signal from T605/5 and 6 is applied to D641 Bridge Rectifier. The negative side

of D641 is connected through R643 to ground; therefore the Audio B+ floats

slightly above ground level. The voltage output from D641 is filtered by C641

and then sent to CN642/1 and 2 unregulated. The audio B+ is used only by the

Audio Output Amplifier IC1461 located on the AK board. One step in

troubleshooting a set that is shut down is to disconnect CN642. If the set

still operates, then replace IC1461 Audio Output. Be sure to discharge the

voltage at CN642/1 and 2 before reattaching the connector to CN642.

Flyback Secondary

Voltages Distribution

The

following voltages are scan derived. This means that some windings of the

flyback transformer have their signals rectified to create additional power

supply lines:

200 Volts C Board IC1701 CRT Amp

+12 Volts A Board IC501 Pin Control, IC561 V Out

-15 Volts IC501 Pin Control, IC561 V Out, Q511 Pin Drive, WA Board IC961 N/S

Amp

The scan-derived supplies are developed when the output from Q502 H Out is

input to T503 Flyback Transformer. This signal is used to create the boosted B+

(+200) on the primary side and the +12 and –15 volts on the secondary side. The

signal from T503/4 is sent through R553 and rectified by D534. This voltage is

output from CN503/5 on the A board to CN503 on the C board. This voltage is

used to supply IC1761 CRT Amp on the C board. This connector can be

disconnected to check to see if the problem is with IC1761 CRT Amp.

The +12 volt line is

derived from the signal at T503/9. It is sent through R537 and rectified by

D531. In the event that a short occurs on this line, R537 may open. Since the

vertical output is supplied by this line, R537 should always be checked if a

vertical output failure is suspected.

The -15 volt line is derived from the signal at T503/7. It is sent through R536

and rectified by D530. In the event that a short occurs on this line, R536 may open. Since the vertical output is

supplied by this line, R536 should always be checked if a vertical output

failure is suspected.

In addition to the scan derived supply voltages, T503 Flyback Transformer also

develops heater voltage from T503/5. T503 also develops high voltage, focus

voltage and ABL [Automatic Brightness Limiter]

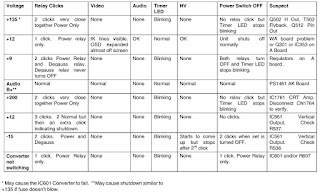

The table below describes

various symptoms that can occur if there is a short on any of the power supply

lines. These types of problems occur when major components being supplied fail

by shorting. An example would be if the audio amp were to fail the set might

shut down as if the Audio B+ line were shorted.

Many

times observing all the symptoms can lead you towards the correct failed

component or problem. All of your senses should be used when troubleshooting.

What you see, hear and smell can often lead you to quick fix

Power Supply Protection

There are three different

circuits that can activate the protection latch.

One is the OCP (Over Current Protection) for the +135 volt line. The other two

are related to the voltage from T605/3 Foldback Winding. When one of these

circuits activates the latch, RY600 is turned OFF. This disconnects the AC from

the circuit that develops Converter B+ and can be noticed during

troubleshooting when two clicks are heard in quick succession.

Latch

Placing

a HIGH on Q653/B activates the latch. This turns ON Q653 that turns ON Q652.

Once Q652 turns ON, its conduction keeps Q653 ON until power is disconnected.

This places a LOW at Q648/B, turning it OFF. This causes RY600 Power Relay to

open and the set turns OFF.

+135

Over Current Protection

Over

current is detected by monitoring the voltage across R652. When this voltage,

which rises as more current is drawn, gets to a level that causes Q651 to turn

ON, the latch will be activated.

Vcc

Rectified Low Voltage Protect (LVP)

The

signal from T605/3 is sent through R601 and rectified by D603. This voltage is

filtered by C618. It is important that this voltage be at a certain level since

it is used to control regulation. Therefore a circuit is constructed in which

Q623 is normally ON. This transistor is ON because D607 should always have

sufficient bias to turn ON. This will place Q623/C at close to ground level.

This keeps D604 and D608 from conducting and activating the latch circuit. If

this voltage were to fall below a certain level, D607 would turn OFF, causing

Q623 to turn OFF. When Q623 is OFF, the +12 volt line would cause D604 and D608

to turn ON, activating the latch.

Foldback

The

foldback circuit is a type of protection circuit that uses a winding on T605

PIT to monitor the current drawn by its secondary. This voltage is rectified

and called Vcc Rect. Q624 is set up with the Vcc Rectifier voltage input to the

emitter. Its base is connected to the Rectified +12 volt line from the

secondary side of the supply, through D605 and R609. D605 is a zener diode

whose breakover voltage is 13 volts.

This circuit will protect against two failures. The first is a rise in the Vcc Rect.

This voltage is developed by the foldback winding of T605. This winding is used

as a current mirror. This means that the more current drawn on the secondary of

T605 PIT, the higher the voltage at T605/3.

When too much current is drawn from the secondary, Q624 would turn ON because

of the increase in voltage across R610. If this occurs, the latch and soft

start circuits will be activated. Soft start is activated to lower the output

supply voltage by increasing the switching frequency. The latch’s purpose is to

shut the supply down.

Secondly, if there were a loss of the +12 volt line then D605 would breakover.

This would cause sufficient current flow through R610 and Q624 would turn ON.

If this occurs, the latch and soft start circuits will be activated.

Vertical Deflection

The vertical deflection

stage consists of the Vertical oscillator, Vertical amplifier, Flyback

generator and the Deflection yoke.

The purpose of this stage is to manufacture a magnetic field. The magnetic

field will bring the electron beam gradually from top to bottom (vertically)

and then quickly back to the top (beam retrace) of the screen to start over

again.

Vertical

Oscillator

When

the TV is turned ON, Set +9Vdc appears at Y/C Jungle IC301/33 and 44. The

internal horizontal oscillator begins and is counted down (divided) to 60 Hz to

become the vertical drive signal.

The drive signal is formed into a positive and negative ramp and its amplitude

and linearity are determined by the serial data from IC001 Tuning Micon. If the

data or clock signal at IC355/34 and 35 were missing, there would be NO

vertical drive at IC301/13 and 14.

Vertical

Amplifier

IC561

Vertical Output is a single package vertical amplifier that outputs a waveform

with sufficient amplitude and current to drive the deflection yoke. It is

powered by +12 and –15 volts from the flyback transformer secondary.

Flyback

/ Boost Generator

The

vertical boost signal is used to generate extra current in the deflection yoke

during the retrace period. This extra current is used to quickly return the

electron beam to the top of the picture.

The flyback generator stage within IC561 uses the vertical signal to make a

30Vp-p pulse needed during retrace time. The retrace portion of the vertical

drive signal input IC561/1 and 7 is extracted and amplified, and appears at pin

3 as a 30Vp-p pulse. It passes through C565 to provide sufficient current to

power IC561/6 during retrace time.

Diode D561 blocks this pulse from the +12 volt source.

The vertical flyback pulse from IC561/3 is sent to the WA board to be used by

the Quadra Pole Focus circuit. It is also goes to C564. C654 blocks any DC and

allows the flyback pulses to be applied to Q652/B.

These pulses keep Q652 ON

and prevents C563 from charging. Therefore Q561 is always OFF while the set is

operating normally. If the vertical flyback pulses were missing, the voltage

from the 12-volt line through R570 would forward bias Q561 B-E. This would

apply a low to IC355/15 VM Out/V Protect. If IC355/15 were to receive a LOW,

the IC would blank the video. If there were problems in this area when the unit

is initially turned ON, the result would be similar to an AKB problem. The

degauss relay would not turn OFF and the Timer LED would be flashing.

Deflection

yoke

The

deflection yoke translates the electrical current flowing through its coils

into a magnetic field that positions the election beam vertically.

Current flowing through the deflection yoke coil is returned to ground through

R578, R563 and R559 and TH501, which are in series. The thermistor is used for

temperature compensation. As the vertical yoke draws more current, the

resistance of TH501 lowers, allowing more current to flow to the yokes. The

voltage developed across these resistors is fed back to the inverting input of

IC561/1 through R566 to improve linearity.

Horizontal Deflection

Block

The horizontal deflection

block creates the signal that drives the horizontal yoke and also drives the

flyback transformer to create the necessary high voltage, focus voltage and

other voltages used by the set.

The HD signal originates from the Y/C/J. The HD signal is applied to the amplifiers

in the H drive and H Out circuits. The signal that exits the H Out transistor

is applied to the flyback transformer and the deflection yoke.

The deflection yoke uses magnetic fields formed by the current through it to

drive the beam across the screen. Feedback from the yoke is coupled to the

centering and linearity circuits. This circuit ensures that the picture will be

linear and centered properly. These circuits work in conjunction with the pin

amp on the return to the H Out.

The purpose of the

pincushion circuit is to correct for deflection distortion, which occurs

because of the yoke’s inability to create a linear beam scan.

The result would be a picture bowed at the sides. We compensate for this problem

by using pincushion correction circuits to control the amount of current that

can flow through the horizontal output’s return.

More current is delivered so the beam can be pushed to the sides of the tube

when necessary. The drive for the Pin amp is created in the Y/C/J and is called

E/W drive. It is applied to the Pin amp with a sample of the HP pulse. Q512

controls the current through the H Out return.

A protection circuit also monitors the HP signal. This protection circuit allows

HP signals to pass to the Y/C/J if the Pin amp and H Out circuits are operating

normally. In the event of a failure, the HP/Hoff line to the Y/C/J would go

LOW. The Y/C/J would then disable HD, which would cause high voltage to be

lost.

Horizontal Out

The horizontal output

circuit consists of the Horizontal

Oscillator, Horizontal Drive, Horizontal Output, Flyback and Horizontal

Centering and Linearity.

Horizontal

Oscillator

When

the TV is turned ON, Set +9Vdc appears and is applied to Y/C Jungle IC355/33

and 44. IC355 contains a horizontal oscillator that is shaped into a horizontal

drive pulse that leaves at pin 19.

Horizontal Drive

Q501

amplifies this HD signal and outputs the signal from its collector.

This signal is coupled by T501 to drive the horizontal output Q502 B-E junction.

Horizontal Output

Q502

is the H output transistor and it drives two circuits:

The deflection yoke – Develops a magnetic field in order to move the electron

beam from left to right on the screen.

The flyback transformers – Develops high, focus and screen voltages.

The scan derived power supplies are also developed here. They are +200 volts,

+12 volts and –15 volts for the CRT Amp and TV’s vertical section. Heater

voltage for the tube’s filament is also developed here.

The horizontal protection circuit also uses the heater voltage.

The HP pulse is fed back to monitor the frequency of the horizontal oscillator.

The horizontal output is also modulated by Q512 Pin Out. This is necessary to

correct for pincushion distortion that would be seen if correction were not

used.

Horizontal

Cantering and Linearity

Changing the DC voltage at the return line of the

horizontal yoke performs horizontal Centering. The +135 volt line is switched

through a series of voltage dividers using S501 and S502. The different

combination of switch settings changes the DC level at the yoke return and,

consequently, the centering of the picture.

Horizontal linearity is determined by feeding back the yoke return signal through

an elaborate filter network, which is made up of T505 and its associated

components to reference of the horizontal output.

Pincushion

The purpose of the

pincushion circuit is to correct for deflection distortion.

This distortion occurs because of the yokes inability to create a linear beam

scan. The result would be a picture bowed at the sides. We compensate for this

problem by using pincushion correction circuits to control the amount of

current that can flow through the horizontal output’s return. More current is delivered so the beam can be

pushed to the sides of the tube when necessary.

Circuit

Description

The

E/W signal from IC355/11 is input to IC501 Pin Control at its inverting input.

A sample of the ABL signal from T503/11 is also input to this same input.

The main HP signal from C510 in the Horizontal Output section is applied to

R524. The signal is applied to a clamp that consists of D518, D523 and D524. It

is also applied to R525 and D516. This signal is now stripped of its negative

component and integrated by C530. This signal is then applied to IC501/5

non-inverting input. IC501 Pin Control compares the inverting and non-inverting

inputs and outputs their difference. The result is output at IC501/7.

This signal is then

applied to the base of Q511 Pin Out. The signal is inverted by Q511 and then

input to the base of Q512. The result is that a PWM waveform is seen at Q512/C.

Q512/C is connected to the return for the horizontal output. When Q512 Pin Out

is conducting it allows more current to be drawn by the horizontal yoke. The

conduction of Q512 is set up so that more current is drawn during the middle

edges of the scanning of a horizontal line. The result is shown where the

output leaves this circuit at R526.

The H Protect circuit will remove the horizontal drive signal if the HP pulses are

not input to IC501/5. This will also occur if Q511 or Q512 short.

H Protect

The H protect circuit is

used to shut down the horizontal deflection circuit if the high voltage should

rise above the acceptable level or if the pincushion drive circuit. Pulses from

the flyback transformer’s heater winding are compared against a reference

voltage. The reference voltage can be removed based on the condition of the Pin

Out circuit. Loss of Pin Out will cause horizontal protection to be indicated.

When H protect is detected, HP pulses will be removed from IC355/19 HP/Hoff.

Video and HV will be disabled, but the power supply will continue to function.

Circuit

Description

When

the horizontal circuit is operating normally, a signal is output from T503/5

that is used to supply voltage to the filaments of the tube. At this point

R550, R529, C531 and C532 filter the signal to a DC voltage. This DC voltage is

input to IC501/3 non-inverting input. This voltage is compared to a reference

voltage of 8.2 volts. This reference voltage is derived by a voltage divider

consisting of R533, D520 and D521. As long as IC501/2 is greater than IC501/3,

the horizontal circuit is operating normally.

IC501/2 is also connected

to Q503/C. Q503 is OFF as long as the signal from the Pin Out circuit is

working normally. If the Pin Out signal were missing, Q504, which is normally

ON, would turn OFF. If Q504 were to turn OFF, Q503 would turn ON. This would

place IC501/2 at ground potential. In that case, IC501/1 would output +12 volts

that would turn Q301 ON and ground the HP signal that is connected to Q301. If

Q301 turns ON, IC355 would shut OFF the drive signal at IC355/19 HD. When the

drive signal is removed, the High Voltage is removed from the set.

This will cause a no video condition, but the Timer LED will not begin to blink.

If the set is turned on with a failure that causes H protect to occur, High Voltage

would begin to come up and then disappear. The timer LED would blink to

indicate that the AKB circuit did not unblank the video. The Timer LED only

indicates an AKB failure when the set is turned from OFF to ON.

Some common complaints

and solutions

KV-27FV15, KV-32FS10,

KV-32FV15

KV-32XBR250, KV-36FS10,

KV-36FV15

KV-36XBR250

Blinking Picture With

Local Weather Channel

On the Weather Channel

when the program switches from the national to local weather the picture may,

jump, blink, or may blank out.

If the customer should

complain about the symptoms above then please check in the Service Mode that

VSS=1. If not change VSS to 1 and recheck to verify if the problem is solved if

the symptom is still present then change the jungle IC355, on the A Board, with

the new type below. The adjustments for Vertical, Horizontal, Color, and Hue

will also needed to be re-adjusted.

KV-27FV15, KV-32FS10,

KV-36FS10

KV-32FV15, KV-36FV15,

KV-32XBR250

KV-36XBR250

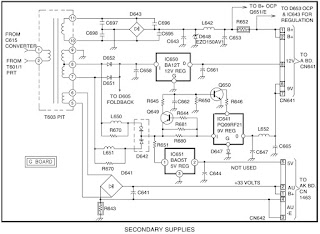

G Board Schematic

Correction

On the G Board Schematic

the winding connections inside T605 is incorrect.

The windings between T605/pins 1 & 2, and windings 3 & 4 are missing.

Please

refer to the corrected schematic below. The proper connections have a winding

between T605/pin 1 & 2, and T605/pin 3 & 4. There is no winding between

T605/pins 2 & 3

KV-32FS10, KV-32FV15,

KV-36FS10

KV-36FV15, KV-32XBR250, KV-36XBR250

V Bow and H Trap

Adjustments

V Bow and H Trap

Adjustments are missing from the Service Manual

If the customer

complains of poor geometry, (trapezoidal or bowing) the following adjustments

might be needed.

V-Bow Geometry distortion;

like the picture in Fig 1 can be readjusted by using the Y-Magnets. The

Y-Magnet is located on the Neck Assembly CRT side.

Adjust the taps

simultaneously to achieve the best geometry. After adjusting this magnet,

please confirm the over all geometry again. (V-Trap, etc could also affect the

geometry as well.)

H Trap Distortion:

If H-Trapezoid geometry is

present, you can adjust the H trap (RV941) on the WA Board. (See Fig)

After adjusting check the overall geometry again since V Bow can also affect

the Trapezoid distortion.

KV-27FV15, KV-32FS10,

KV-36FS10

KV-32FV15, KV-36FV15, KV-32XBR250

KV-36XBR250

S-Link, IR Headphone, OSD,

and 3D Comb Filter Mis-Operation

The following Symptoms may

occur:

1. S-LinK: When the TV detects the S-Link signal in stand-by mode. TV is

supposed to automatically turn on and select appropriate video input. It does

turn on, but it does not select the appropriate input.

2. OSD: When customer tries to enter password for V-chip in Spanish

menu, customer will see additional unnecessary letters Pr preceding correct

OSD.

3. IR Headphone: In XBR models only. When customer swaps audio of main picture

and PIP picture, customer can hear the audio of PIP picture even when it is

supposed to be blocked.

4. 3D Comb Filter: In XBR model only, when customer changes video input

from S to composite, customer can see a Black & White picture, less than

one second, then color returns.

|

27 inch models: |

1. In the service Mode

record on paper the following register information in both RF & Video mode:

|

VP SHUE |

RF Data ______ |

Video Data:_______ |

2.

1) Replace the CPU (IC001)

2) Enter the service Mode using the remote. Then press 8 then Enter. This will reset the CPU, turning the set off

then back on automatically.

3) Re-enter the Service Mode.

4) In the RF mode replace the data in the SHUE, SCOL, & SSHP with the recorded

data from the original CPU.

5) In the Video mode replace the data in the SHUE, SCOL, & SSHP with the recorded

data from the original CPU.

6) Change the Data of ID7 from 0 to 2.

7) Write the new data into the CPU using the remote press the Mute then Enter

key.

Non XBR Models:

1. In the service Mode record on paper the

following register information in both RF & Video mode:

|

VP SSHP |

RF Data ______ |

Video Data:_______ |

2. 1) Replace the CPU (IC001)

2) Enter the service Mode using the remote. Then press “8” then “Enter.” This will reset the CPU, turning the set off

then back on automatically.

3) Re-enter the Service Mode.

4) In the RF mode replace the data in the 2SHU, 2COL, & SSHP with the recorded

data from the original CPU.

5) In the Video mode replace the data in the 2SHU, 2COL, & SSHP with the recorded

data from the original CPU.

6) Change the Data of ID7 from 0 to 2.

7) Write the new data into the CPU using the remote press the “Mute” then

“Enter” key.

32/36 XBR models:

1. In the service Mode record on paper the following register information

in both RF & Video mode:

|

VP SSHP |

RF Data ______ |

Video Data:_______ |

2.

1) Replace the CPU

(IC001)

2) Enter the service Mode using the remote. Then press “8” then “Enter.” This will reset the CPU, turning the set off

then back on automatically.

3) Re-enter the Service Mode.

4) In the RF mode replace the data in the 2SHU, 2COL, & SSHP with the recorded

data from the original CPU.

5) In the Video mode replace the data in the 2SHU, 2COL, & SSHP with the recorded

data from the original CPU.

6) Change the Data of ID7 from 9 to 11.

7) Write the new data into the CPU using the remote press the “Mute” then

“Enter” key.