GAMMA RAYS

The

first device that springs to mind when thinking about measuring radioactivity

is the Geiger-Müller tube. However, these counter tubes are getting hard to

find and expensive, and even if you do manage to get hold of one, you will

still need to find a way to generate its operating voltage of several hundred

volts. It is less well known that even a humble photodiode such as the BPW34

can be used to detect X-rays and gamma radiation.

Radiation detector

Ionizing

radiation is potentially harmful to health, and it is important to minimize

one’s exposure to it as far as possible. A simple Geiger counter with a small

glass mantle tube will not usually be adequate to detect possibly harmful

radiation. The semiconductor sensor we describe below also has a relatively low

sensitivity, only being able to detect fairly intense sources of radiation, but

it is nevertheless an interesting device for carrying out experiments and

measurements. An advantage of using a photodiode is its small sensitive area.

The background rate due to cosmic rays is very low and signals from small

samples are easier to detect than with a counter tube.

Radiation

When considering protection from radiation it is gamma rays that are the most important. They can penetrate walls and it is difficult to block them. Hard gamma rays are present in the environment all around us and are also not stopped even by a thick wall. Alpha particles, on the other hand, only have a short range and generally cannot even penetrate a sheet of paper: this is the reason that many counter tubes cannot detect them, unless they have a very thin mica window. Beta particles have a longer range and can penetrate thin sheets of metal. Most counter tubes are mainly designed for detecting gamma rays while, within certain limitations, also being sensitive to beta particles.

When considering protection from radiation it is gamma rays that are the most important. They can penetrate walls and it is difficult to block them. Hard gamma rays are present in the environment all around us and are also not stopped even by a thick wall. Alpha particles, on the other hand, only have a short range and generally cannot even penetrate a sheet of paper: this is the reason that many counter tubes cannot detect them, unless they have a very thin mica window. Beta particles have a longer range and can penetrate thin sheets of metal. Most counter tubes are mainly designed for detecting gamma rays while, within certain limitations, also being sensitive to beta particles.

Diode as detector

The behavior of a type BPW34 PIN photodiode is similar to that of a low-cost counter tube. Alpha particles will be stopped by the plastic enclosure of the device, whereas gamma rays pass through without problem and create many electron-hole pairs in the diode’s depletion layer. If the diode is reverse-biased, almost all of the charge carriers will be drawn away: this corresponds to a small current pulse which can be amplified and processed. Beta particles can also generate such a signal if they are sufficiently energetic to reach the depletion layer.

The behavior of a type BPW34 PIN photodiode is similar to that of a low-cost counter tube. Alpha particles will be stopped by the plastic enclosure of the device, whereas gamma rays pass through without problem and create many electron-hole pairs in the diode’s depletion layer. If the diode is reverse-biased, almost all of the charge carriers will be drawn away: this corresponds to a small current pulse which can be amplified and processed. Beta particles can also generate such a signal if they are sufficiently energetic to reach the depletion layer.

The

amplitude of the signal produced by the photodiode is considerably smaller than

that of normally obtained from a counter tube, and so a very low-noise

instrumentation amplifier circuit is needed. Another requirement when using a

photodiode as a beta and gamma radiation detector is that light must be

completely excluded, as otherwise the photocurrent will overwhelm the signal we

are looking for. In our prototype we used ordinary aluminum kitchen foil as a

screen. The difference between PIN diodes and PN diodes is that the former

include an extra very lightly N-doped region called the ‘intrinsic’, or ‘i’

region. This high-resistance region lies between the ‘n’ and ‘p’ regions. The

result is a wider depletion layer in the diode, and hence a greater volume of

semiconductor that can interact with photons.

The

structure is used in a photodiode in order to obtain as many charge carriers as

possible per photon, optimizing the device’s sensitivity. Another way to

increase sensitivity is to increase the sensitive area of the device. However,

this has the disadvantage of increasing its capacitance, which reduces the

(voltage) amplitude of its output signal. Commercially-available semiconductor

radiation detectors have a large area and a wide intrinsic region. Simple PIN

photodiodes such as the BPW34 are less sensitive than these devices, but also

of course somewhat cheaper. The BPW34 and BPX61 photodiodes are practically identical apart from their enclosures. The (cheaper) BPW34 comes in

a plastic package, whereas the BPX61 comes in a TO-5 metal enclosure with a

glass window. It is possible to remove this window (carefully!) to expose the

chip: this will make the diode capable of detecting alpha particles.

The rays or particles must first make it through a 15 µm thick piece of aluminum (the thickness of ordinary kitchen foil). This is no obstacle to gamma rays and beta particles, and alpha particles with an energy of 4 MeV or more will also pass through. When the particle enters the plastic of the photodiode package, deceleration radiation (German: ‘bremsstrahlung’) will be produced in the form of brief flashes of light, which can also sometimes be detected by the sensor. It is therefore not impossible for even the BPW34 to have some sensitivity to alpha particles.

The rays or particles must first make it through a 15 µm thick piece of aluminum (the thickness of ordinary kitchen foil). This is no obstacle to gamma rays and beta particles, and alpha particles with an energy of 4 MeV or more will also pass through. When the particle enters the plastic of the photodiode package, deceleration radiation (German: ‘bremsstrahlung’) will be produced in the form of brief flashes of light, which can also sometimes be detected by the sensor. It is therefore not impossible for even the BPW34 to have some sensitivity to alpha particles.

In

principle any semiconductor is sensitive to ionizing radiation. It is perhaps

less surprising, then, that a photodiode is sensitive to radiation than that

the effect has not been widely remarked on before. The effect is however well

known in dynamic RAMs, whose stored data can be corrupted by incident

radiation. The problem of building electronics to withstand the higher levels

of radiation found in space is becoming increasingly difficult, because as

structures get smaller it becomes increasingly likely that a single energetic

particle can interfere with the operation of a circuit.

Amplifier

Charge amplifiers are usually constructed using a low-noise FET-input op-amp as the input stage. Here let's take an alternative approach:

Charge amplifiers are usually constructed using a low-noise FET-input op-amp as the input stage. Here let's take an alternative approach:

Figure above shows the circuit

of the sensor amplifier. Two transistors are used to amplify the signal from

the photodiode. The direct-coupled amplifier automatically sets itself to a

mid-range operating point, which gets a good signal to-noise ratio from the

low-noise BC549C transistors.

The

transistor input of the amplifier has comparatively low impedance, which gives

good noise matching. As a result of its base-collector capacitance the first

stage also operates as an integrator: this turns the brief pulses from the photodiode

into longer pulses which can then more easily be amplified.

Sensitivity

can also be increased by increasing the reverse voltage on the diode. This

reduces the capacitance of the diode and increases the size of the depletion

layer. The voltage can be as high as 32V, although the optimum value probably

lies somewhat lower: the diode already operates well at 9 V. It is also

possible to wire two or more photodiodes in parallel, and that way it is

possible to achieve a sensitivity on a par with that of a small counter tube

such as the ZP1310. An oscilloscope can be connected to the output of the

circuit to view the signal. Readers who yearn for the clicking sound of a

‘real’ Geiger counter should consult the text box ‘From radiation to sound’ for

a suitable solution.

Construction

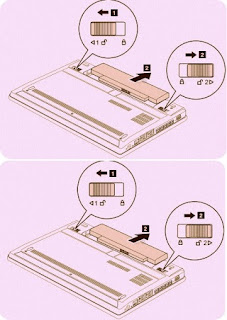

The circuit can be built on a piece of breadboard, with the photodiode on the underside . To keep light out of the sensor the whole circuit is wrapped in aluminum foil . As mentioned above, ordinary kitchen foil is ideal for this as it is thin enough to let beta particles through. The foil also functions as electrical screening. To avoid the foil causing short circuits, wrap the board first in insulating tape, leaving a gap for the window of the photodiode. Then wrap the assembly in foil, not forgetting to connect the foil to ground.

The circuit can be built on a piece of breadboard, with the photodiode on the underside . To keep light out of the sensor the whole circuit is wrapped in aluminum foil . As mentioned above, ordinary kitchen foil is ideal for this as it is thin enough to let beta particles through. The foil also functions as electrical screening. To avoid the foil causing short circuits, wrap the board first in insulating tape, leaving a gap for the window of the photodiode. Then wrap the assembly in foil, not forgetting to connect the foil to ground.

Amplifier circuit for the detector